Inspection Plug

Standard Inspection Plugs are designed to assist in Non Destructive Testing (NDT) programs on insulated and non-insulated pipe and vessels. These plugs are designed to withstand temperatures up to 500º F and are available in both Aluminum and Stainless Steel versions. They also provide a method of sealing test holes in insulation for ultrasonic testing of metal thickness or visual inspection for external corrosion of insulated equipment in hot or cold service.

Available in:

- Aluminum version:

- Aluminum Alloy 3003, Temper O. .032 THK

- Physical Properties: Ultimate Tensile Strength (UTSI)= 17.8-17.9

- Typical Yield (TYSI)=7.5-7.6 Elongation (EL4D)= 28.5-29.5

- Stainless Steel version (Optional):

- Steel alloy T304 Annealed 3B Finish 8% Minimum Nickel. .020” THK

- Physical Analysis: YLD2%-43300 TENSL=101000 ELONG=61 R155T=83 Gain=8

- Strain Relief Washer Molded into Plug:

- Stainless Steel Flat washer .156 x .375 x .049 (to provide strain relief for lanyard)

- Lanyard Assembly:

- 1/16” 7 x 7 Stainless Steel Wire Rope/Flexible Aircraft Style

- Construction: 7 Strands with 7 wires per strand.

- Alloy: 302/304 Stainless Steel/Copper Oval Pressed Sleeve

- Material: Copper per. Type 102 (UNS C10200) or Type 103 (UNS C10300) or Type 122 (UNS C12200) in accordance

- with ASTM 875

- Silicone Plug:

- Compound #SVX-16194A-6 RED Silicone.

- Compression Molded Physical Properties: Durometer A = 45-55, Tensile > 700, Elongation > 350%, Tear Die B > 50.

- High resistance to ultraviolet radiation.

- O” Ring:

- Compound #N7001 Nitrile Physical Properties: Durometer A=70, Tensile=2130, Elongation=470%

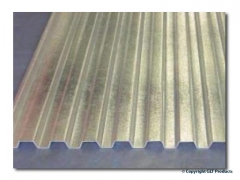

- Corrugated Transition Gasket:

- Compound #110-60 Neoprene

- Physical Properties: Hardness, Shore A=60, Ultimate Tensile 2770 PSI, Elongation=625%, Tear=318PSI.

- High resistance to ultraviolet radiation. Available for 2 ½”, 4” and 5” Flanges)

Available Sizes:

- 1¾” Contoured for 5”-6” O.D. jacketing

- 1¾” Flat

- 4” Flat 1 ¼” Corrugated transition gasket available

- 5” Flat 1 ¼” Corrugated transition gasket available

© Specialty Distribution Group, LLC, a Virginia limited liability company d/b/a GLT Products.

All rights reserved.

All rights reserved.