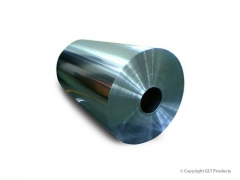

Stainless Steel Jacketing

Stainless Steel Roll Jacketing is manufactured from T-304 and T-316 prime grade Stainless Steels. These alloys comply with ASTM A-240, and are supplied with a regular dull finish for reduced glare. The yield strength is 30,000-45,000 PSI and the tensile strength is 75,000-110,000 PSI.

These alloys are of a special soft-annealed temper, for ease in fabrication. T-304 is normally used in all except the most corrosive areas, where T-316 is recommended.

Stainless Steel is available in smooth, stucco embossed, or 3/16" corrugated roll jacketing, and deep corrugated sheets. Jacketing is recommended for insulated piping, tanks, and vessels less than 8 feet in diameter. Deep corrugated sheets are recommended for diameters greater than 8 feet. It is recommended that the roll jacketing be 3/16" corrugated for the following reasons: it is stronger than smooth, it reduces glare from external light sources, it eliminates "coil break" when applied over small size piping and does not show dents readily. In extremely corrosive environments, smooth jacketing is recommended to facilitate run-off.

Recommended Use:

- Chemical Plants and Refineries: Urea units, fertilizer plants, caustic facilities, petrochemical plants and aluminum refineries.

- Steel Mills: Coke ovens, oxygen steel making furnaces, byproduct plants, aromatic plants and steam distribution facilities.

- Paper Mills: Digester areas, white and black liquor tanks, bleach tanks, chemical pulping and waste treatment tanks.

- Miscellaneous: Areas of high incidence of abuse on bridges, walkways and service roads, areas of high fire incidence, food processing facilities, packing plants and freeze facilities.

All rights reserved.